February 25th 2021

Tuas (Singapore) fire: The explosive danger of potato powder, sugar, flour and other dust particles.

Potato starch powder has been pinpointed as the source of a explosion at an industrial building in Tuas (Singapore) on Wednesday (Feb 24), which left three workers dead and injured seven others.

Preliminary investigations have found that the incident at 32E Tuas Avenue 11 was caused by “a combustible dust explosion”, said Commissioner for Workplace Safety and Health (WSH) Silas Sng on Thursday.

He added that the dust in this case was potato starch in powder form. The company at the site – Stars Engrg – uses potato starch powder to manufacture its products, said Mr Sng.

As of Thursday night, five of the injured workers remain in hospital in critical condition, while two have been discharged.

CNA explains how potato starch powder – or other dust particles, including commonly found ones such as sugar or flour – can be an explosion hazard.

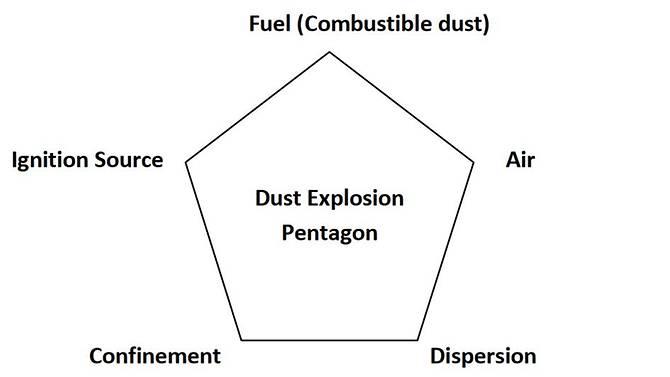

According to a Ministry of Manpower (MOM) circular issued by the Occupational Safety and Health Division in July 2015, fine particles can combust when all five elements of a “dust explosion pentagon” are present: fuel (the combustible dust), air, dispersion, confinement and ignition source.

“It is a known scientific fact that … materials in powder form can be explosive when it is dispersed over the air,” said Mr Sng, who is also director of the Occupational Safety and Health Division, on Thursday.

“Especially when they are in an enclosed environment … with a source of ignition, you get an explosion, as you see in this case here,” he added.

In such dust explosions – which happen “often but not always in an enclosed location” – the fine particles that are suspended in air experience “rapid combustion”, said the MOM circular.

And what differentiates dust explosions from fires linked to a mass of solid material is the size of the combustible surface area.

“A mass of solid combustible materials will burn relatively slowly due to the limited surface area exposed to the air. However, when the same solid is divided into fine powder and dispersed as suspended particles in air in the form of dust cloud, the result will be quite different,” said MOM in the circular.

“In this case, the surface area exposed to the air is much larger, and if ignition occurs, the whole of the cloud may burn very rapidly. This results in a rapid release of heat and gaseous products, causing pressure to rise.”

Materials that are combustible in dust form include organic matter, such as sugar, corn starch, flour, peat, soot and cellulose pulp, according to MOM’s circular.

Various types of chemical particles are also combustible, including ascorbic acid (Vitamin C) and sulphur.

Metals such as aluminium, bronze, magnesium and zinc can also catch fire in powder form, as can plastics such as resins, melamine and polymers.

The WSH commissioner on Thursday explained that combustible dust can be generated when powder is transferred, for example from a bag into a mixer.

“Over time, the dust can accumulate in the environment, especially if the ventilation or the housekeeping is inadequate,” said Mr Sng.

As such, dust control is one of the measures recommended to minimise fire risks.

The MOM circular suggested having local exhaust ventilation systems that “can capture dusts effectively to prevent unnecessary dispersion of combustible dusts where people are at work”.

Such systems can be implemented at suitable locations where materials are loaded, unloaded or transferred, while “taking care to not to have an extensive ducting network, which can cause burning materials to spread following an explosion” within the ventilation system, said MOM.

The ministry also recommended housekeeping and maintenance of dust collection system and filters, with vacuuming or wet cleaning methods preferred over sweeping methods. “Sweeping would tend to cause more dispersion of dust particles,” it said.

To prevent ignition, MOM said flame-proof equipment or non-sparking tools should be used in areas where combustible powders are handled.

Operators should also ensure effective bonding and grounding of powder handling units to prevent the accumulation of electrostatic charges, which may lead to ignition when inadvertently discharged.

Inert gases such as nitrogen can be used to reduce or eliminate the presence of oxygen in the atmosphere.

MOM also recommended other measures such as providing explosion relief to safely vent the energy in the event of an explosion, installing detectors for sparks or glowing materials, and isolating areas handling combustible dusts from other parts of the workplace.

And on top of providing training and refresher courses on combustible dust hazards, employers must equip workers with the right personal protective equipment such as fire retardant clothing and safety shoes.

Source: https://www.straitstimes.com/singapore/explosion-in-tuas-industrial-building-on-wednesday-claims-three-lives