April 11th 2024

Tereos and Futerro team up to produce bioplastic from wheat-based dextrose.

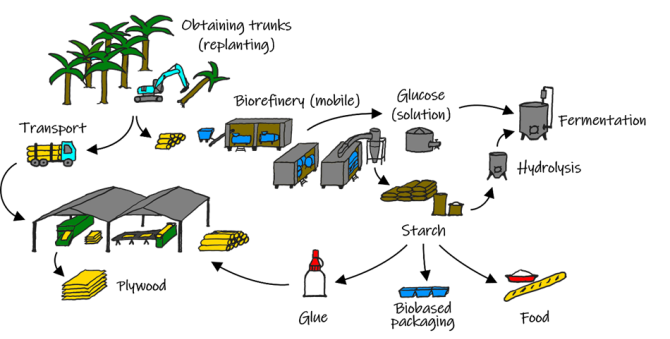

Futerro, a Belgian pioneer and leader in the production of lactic acid, lactide and polylactic acid – PLA – and Tereos, a cooperative group active in the sugar, ethanol and starch markets, have signed a supply agreement that paves the way for the creation of a new biomanufacturing platform. Under the agreement, Tereos undertakes to supply Futerro annually with 150,000 tonnes of dextrose derived from wheat starch produced at its Lillebonne plant, which Futerro will use to produce various bio-based platform molecules and PLA at the new biorefinery it plans to construct. The project will be located in the industrial-port area of Port-Jérôme-Sur-Seine. The integrated plant, with a projected initial capacity of 75,000 per annum, will go into operation in 2027.

The Tereos plant in Lillebonne processes more than 800,000 tonnes of French wheat per year. To meet the agreed volume of dextrose, some €30 million will soon be invested in adapting the production facilities.

“Tereos is the third-biggest producer of starch products in Europe. Our expertise in maximising the value of plant-based raw materials such as wheat means that we produce quality dextrose. This partnership with Futerro heralds the creation of a new industrial sector around green chemistry and strengthens our position in this market of the future,” said Olivier Leducq, managing director of Tereos.

This kind of short supply chain, combined with local production, offers environmental benefits in terms of logistics and the optimum utilisation of agricultural by-products.

A pipeline system will connect the two neighbouring plants, optimising dextrose logistics. Futerro currently estimates that nearly 50% of its logistics flows will avoid road transport.

An estimated 1,150 jobs will be created along the new value chain between the two companies, 250 directly and 900 indirectly.

“This strategic alliance highlights the crucial role of green chemistry as a driving force for innovation. Thanks to the support of our partners, we believe our biorefinery project will make a significant contribution to a positive transition for the sector, the Normandy basin and France as a whole. It builds on efforts to address the environmental and economic challenges that have affected the sector for many years”, said Frédéric Van Gansberghe, CEO of Futerro.

Futerro constructed its first lactic acid polymerisation demonstration plant in Belgium in 2007. The company opened its industrial PLA production unit, with a production capacity of 100,000 tonnes per year, in China in 2021. Its PLA is sold in the market under the Renew brand name. Futerro has developed technologies covering the entire PLA supply chain, from the fermentation of dextrose into lactic acid, to the polymerisation into PLA and finally end-of-life management via its patented molecular recycling technology known as Loopla.

Source: https://www.futerro.com/news-media/futerro-aims-set-new-fully-integrated-pla-biorefinery-normandy-france and https://www.tereos.com/app/uploads/2024/04/press-release-tereos-x-futerro-from-wheat-to-bioplastics-final.pdf