January 10th 2023

Corn prices to remain elevated, says Beroe.

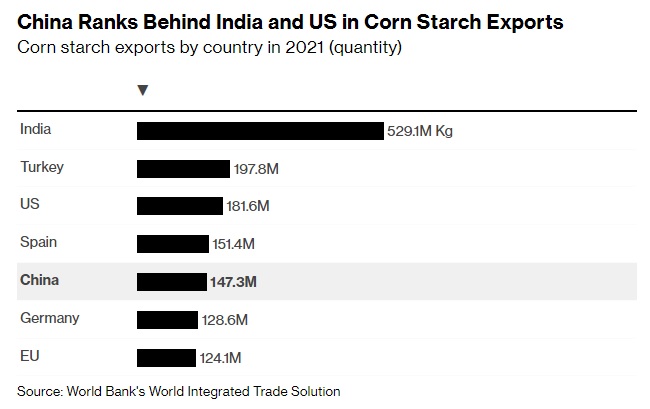

Global corn production has risen by approximately 11 percent over five years as a response to the rise in corn demand by roughly 14 percent during the same period. The end-user industries, including corn starch and animal feed, are the main forces behind supply and demand, impacting price trends.

The key factors driving the growth also include demand from the end-use segments, such as the citric acid market and feed industry in China, Canada switching to green fuels, and increased domestic utilizations in most countries, amid the pandemic. Unfavorable weather conditions in key growing destinations and the loss of Ukrainian grain exports also impacted the global corn market this year.

Since end-use categories are largely concentrated in the U.S. and China, these two nations are the top consumers. Concerning the corn processing end-use segments, citric acid is in high demand post-Coronavirus, while the corn starch market could rise by a CAGR of 4.8 percent in the coming years. This is causing corn demand in the US and China to grow. Top corn processors such as Cargill, ADM, and Ingredion occupy about 70-80 percent of the market share.

LATAM nations have always competed with the US for exports. However, this year dry weather conditions in Brazil, coupled with delayed plantings, are expected to impact second crop quality heavily.

Argentina mainly exports to countries in Asia and the Middle East, with Algeria, Vietnam, Malaysia, and Egypt being the top export destinations. Argentina has sold about 20 MMT of corn in the 2021/22 marketing year. About 1.2 MMT of corn was exported last week of March. Weekly export volumes of corn have surged significantly even amid war conditions.

Corn prices have remained firm and gained significantly owing to worries about the export of shipments via the Black Sea amid strong demands. Ukraine is struggling to export grains via rail as the volumes for export which were earlier shipped through the Odesa terminal, were very high and are not replaceable via rail.

Global supplies remain tight, with Ukraine struggling to export corn, the EU facing a structural deficit, slower pace of the US planting, along with Brazilian crops, threatened by dry weather. CBOT corn prices continue to gain support from these factors amid an acute shortage of fertilizers and rallying freight costs.

The European nations are constantly trying to get Ukrainian grain stocks out of the country through rails. Shipments are currently directed to Austria and Germany. Global corn prices are expected to remain elevated along the short-medium term due to ongoing supply chain disruptions and increasing production costs.

Reduction in corn shipments from Ukraine has caused European farmers to opt for genetically modified animal feed from South America and US. Non-GMO corn from Ukraine constituted half of EU imports. However, 92 percent of US corn imports are GM. Incidentally, EU companies do not have to label meat or animal products fed with GM grains.

China has bought only 126,727 MT of corn from Ukraine, compared to 1.26 MMT in 2021. Corn shipments from all origins to China between January to May fell by 2.9 percent, according to customs data, while only in May did shipment volumes fall by 34.1 percent. The Chinese feed industry demand for corn remains under pressure leading to lowered livestock margins.

Besides the supply crunch and surging corn production costs, logistics is also adding to the corn prices. Fertilizer availability remains grim, which could impact corn quality in top-production countries. The total corn production cost for the US was $634/acre. The total operating and allocated overhead costs comprise 48.7 percent and 51.3 percent of the total cost, respectively.

Corn is planted during April and May, while harvest usually begins around September. The planting and harvesting of corn influence the price trend cycles in the US. Generally, the prices trend downward between September and December due to harvest. The downward trend continues from January to March as harvest supply enters the market. Prices could then trend upward or downward between April and August, depending on demand and farmer preferences, such as rotation with soy. Costs could become more favorable for procurement as major production countries begin harvest. Supplies from US and Brazil could ease prices in the medium term.

India is planning to launch 20% ethanol mixed gasoline in 2023 to cut down alternate fuel import requirements. Oil prices are hard hit this year, due to which the country is trying to expedite efforts to increase domestic stocks. The government also plans to approve the increased use of feedstock such as corn, sugar, molasses, and damaged grains for biofuel production.

Innovation plays a vital role in the corn industry in developing new varieties for pest, insect, and disease resistance. Innovation is also used for high profitability in end-use markets like the ethanol, polyol, and sweetener industries.

Seed companies are developing new corn varieties and hybrids capable of pest resistance and increasing water use efficiency. Breeding initiatives concentrate on creating more disease-resistant corn hybrids.

Crop protection companies, such as Provivi, are working towards protecting acres of cultivation land from pest infestation. The company is expected to supply pheromone-based Mating Disruption products against Fall Armyworm infestation in corn to small-scale farmers in India.

The National Corn Growers Association is working with US farmers to improve land efficiency by 12 percent, reduce soil erosion by 13 percent, reduce GHG emissions by 13 percent, improve energy use efficiency by 13 percent and increase irrigation water use efficiency by 15 percent. The organization is committed to achieving these targets by 2030.

These efforts have the potential to influence global pricing and sustainability. While the demand for corn varies, production and distribution will always be progressive.

Source: https://www.beroeinc.com/press/corn-prices-to-remain-elevated-says-beroe/