December 13th 2023

Starch from oil palm trunks for food and non-food applications to reduce oil palm footprint.

Oil palms appear not only to be a source of palm oil, they can also contain large amounts of other valuable substances, such as starch. However, the palm oil industry is often accompanied by undesirable deforestation. That is why Wageningen University & Research is conducting research with PalmStarch into extracting starch from the trunk of the palm tree. So that the oil palm will yield more than oil, and less land will be needed for the production of other starch-containing crops. This could be a step towards a more sustainable oil palm industry.

Project leader and researcher Ben van den Broek explains why a study like PalmStarch is so important: “Those plantations are already there, forests were often cut down for them decades ago. We cannot reverse this, but we can use the plantations much better and more sustainably. Within the SustainPalm program, we work with Indonesian partners on all kinds of innovative measures to make palm oil extraction more sustainable. One option is to get more out of the whole oil palm, which means less land is needed and no forest clearing is needed in other places. We are investigating this in PalmStarch.”

When an oil palm plantation becomes old and produces less oil, it is cut down and farmers usually leave the trees on the land. These pieces then serve as nutrition for the soil. This is of course quite a circular approach, but the effect on healthy soil is limited: nutrients are largely washed away, and sugars and starch decay. Just like the rest of the trunk. While there is still value to be gained from that. Using some of these trunks therefore hardly has any negative consequences for the soil, but it does save on other cultivation and provides useful products.

Parts of the trunk are already used for veneer production (sheet material), but it also contains a lot of starch that is now lost. “If you can also extract some starch from the old palm trunk, you don’t have to plant another field of cassava or potatoes, for example,” Van den Broek explains. “We estimate that there is about 5 tons of starch in the trunks per hectare. Previous research shows that this is easy to extract, because it is concentrated in the upper part of the trunk, where the content is approximately the same as in starch potatoes.” This is not possible and not necessary for all trunks. Van den Broek: “It is becoming too labor intensive to extract starch from all the trunks. In addition, not all trunks contain the same amount of starch. So you only want to work with the palms that contain the most starch.”

But how do you know which palm can be used for starch and which cannot? Van den Broek and his colleagues are working on a measuring device that indicates within a few seconds whether there is a lot or little starch in it. Van den Broek: “You have to be able to decide quickly: leave it or take it with you?” Avoiding delay is also important for isolating the starch. “If we leave it for too long, the starch is converted into glucose sugars,” explains Van den Broek. “Starch has more value than glucose, although glucose can be used to make sugar (gula). We are also researching this in the SustainPalm program.”

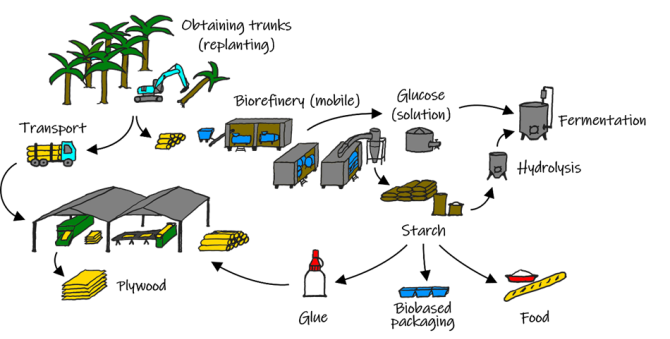

The project is also investigating the most effective way to extract starch from the palm. That’s not that easy. Van den Broek: “There is a lot of silica in the palm trunk. This causes the equipment to wear out faster. Think of cleavers that quickly become blunt.” At the end of this project, the researchers hope to have found a solution for this too. Ultimately, the goal is to develop a mobile factory that produces starch in plantations that are being replanted. This can then be moved to a next location.

One of the reasons Van den Broek is so enthusiastic about this project is its application. “We can make several products from this starch, such as ingredients for food and biopolymers for packaging material. It is also used for breeding insects. How wonderful if, in Malaysia, for example, they can use their own starch for this without additional land demands. But also that we have discovered a new source of starch that has different properties, and therefore also potential for all kinds of new applications.”

This research is carried out on behalf of TKI-AgriFood, and is a collaboration between Wageningen Food & Biobased Research, Bio-tec, Ebbens B.V., PaperFoam, Profina Plywood, Tate & Lyle Solutions and PT Bio Cycle Indo.

Source: https://edepot.wur.nl/640436